70 % faster engine changes

COBRA cuts typical change‑out time from 28 h to as little as 8–9 h

Universal fleet compatibility

one system serves narrow‑ and wide‑body aircraft - validated by both Airbus and Boeing

Ground‑based, safety‑first operation

a four‑pillar, 3‑axis design keeps the engine fully supported at all times

Overview

The COBRA is RH Aero’s universal, semi‑automatic engine‑change system for narrow‑ and wide‑body fleets. Its independent four‑pillar, 3‑axis architecture delivers millimetre‑accurate alignment while allowing technicians to complete a full change‑out up to 70 % faster than traditional methods. Integrated APM, LSF and overload protection keep every lift fully AMM‑compliant, safeguarding both engine and airframe throughout the process.

Details

- Nominal capacity: 16.3 t / 36,000 lb

- Lift stroke: 1 700 mm (Ultra‑Short) or 2 800 mm (Long) 9″

- Horizontal / transversal travel: ±120 mm

Operational Advantages

Universal coverage – interchangeable adapter sets link to all common engine stands, dollies and shipping cradles, enabling COBRA to support the full spectrum of wing‑mounted engines from A220 PW1500 to B777 GE90.

Integrated lifting architecture – synchronised primary‑and‑secondary hydraulic units keep the engine balanced through the complete stroke, eliminating suspended‑load risk.

Precision positioning – servo‑controlled pillars deliver millimetre‑accurate X‑, Y‑ and Z‑movement within ±120 / ±150 mm envelopes and 10° inclination.

Embedded safety suite – Automatic Preload Maintaining (APM), Lowering Safety Function (LSF), overload protection and emergency lowering meet CE & UL standards and all published AMM limits.

Data & diagnostics – 9″ colour HMI provides live load data, step‑by‑step workflow and USB download; optional laser target, inclination sensor and calibration kits extend capability.

Mobility & support – transport trailer, diesel power unit, spare‑parts kit and HYDRO’s global service network ensure rapid deployment and lifecycle support.

Technical Data

Nominal capacity: | up to 18 t / 39,600 lbs |

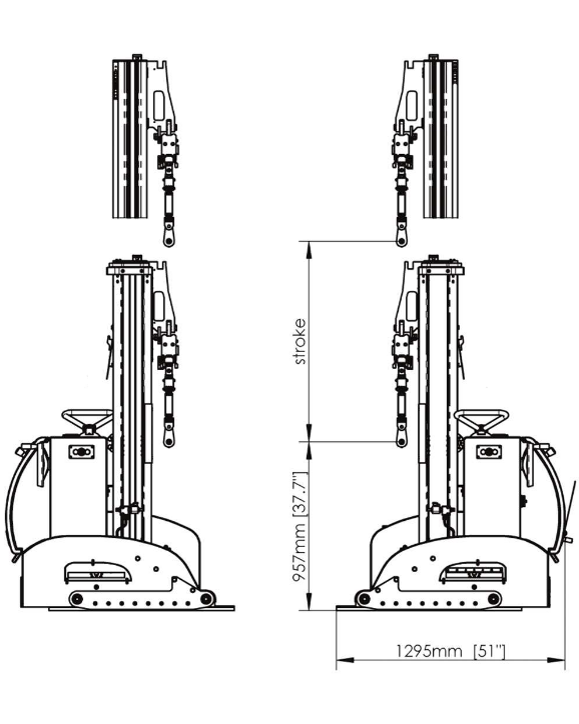

Closed height long pillar: | 2,014 mm / 79.3“ |

Extended height: | 4,814 mm / 189.5“ |

Hydraulic lift: | 2,800 mm / 110" |

Closed height short pillar: | 1,714 mm / 67.5“ |

Extended height: | 3,914 mm / 154.1“ |

Hydraulic lift: | 2,200 mm / 86" |

Max. horizontal movement: | ±120mm / 4” |

Max. transversal movement: | ±150mm / 6” |

Max. inclination longitudinal: | 10° |

Weight primary: | 1,200 kg / 2,645 lbs |

Weight secondary: | 1,048 kg / 2,310 lbs |

OEM approval specific to:

- Aircraft / Engine type

- Engine stand, dolly, cradle

- Lifting equipment

- COBRA Version

Talk to an RH Aero │ HYDRO specialist about lead‑time, pricing and ROI for the COBRA Universal Engine Change System.

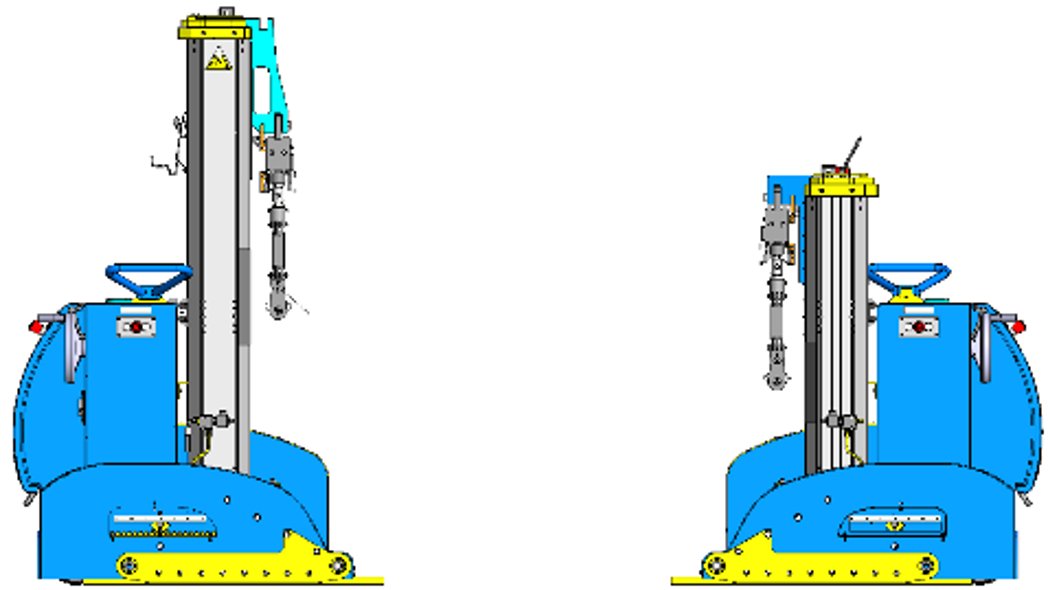

Long - Ultrashort

AirframePrograms:

Airbus A220, A320ceo, A320neo, A330ceo, A330neo, A350

Boeing 737, 757, 767, 777, 777x, 787

Technical Data:

Capacity: 16,3t

Stroke: 2800mm / 1700mm

Lifting Speed: 5mm/s or 10mm/s

Storage Footprint: 2400mm x 2400mm

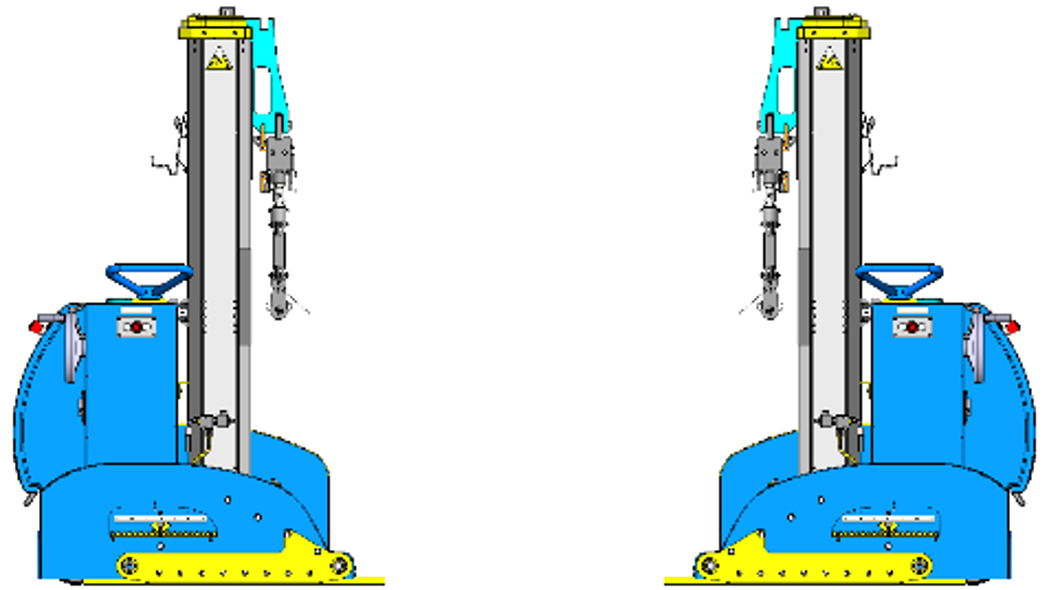

Long - Long

AirframePrograms:

Airbus A320ceo, A320neo, A340, A350, A380

Boeing 747, 757, 767, 777, 777x, 787

Technical Data:

Capacity: 16,3t

Stroke: 2800mm / 2800mm

Lifting Speed: 5mm/s or 10mm/s

Storage Footprint: 2400mm x 2400mm

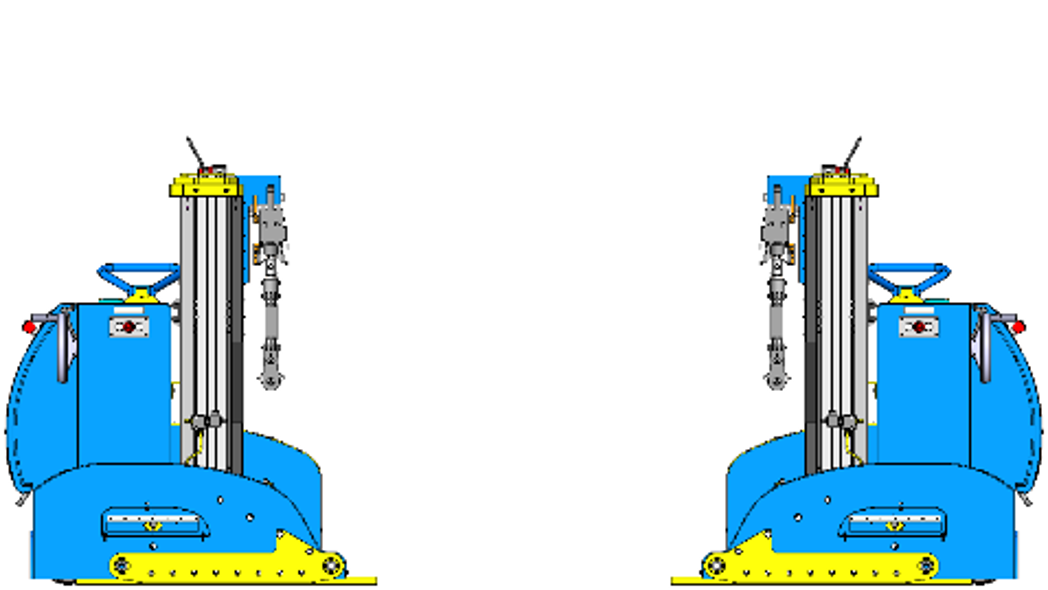

Ultrashort - Ultrashort

AirframePrograms:

Airbus A320ceo, A320neo, A340, A350, A380

Boeing 747, 757, 767, 777, 777x, 787

Technical Data:

Capacity: 12,0t

Stroke: 1700mm / 1700mm

Lifting Speed: 5mm/s or 10mm/s

Storage Footprint: 2400mm x 2400mm

Customer Story

Independent field data confirm that COBRA reduces engine‑change time by up to 70 % relative to bootstrap procedures, cutting a typical Trent 1000 removal‑and‑install from 28 hours to just 9 hours.

Aircraft / Engine: B787 / Trent 1000

Task completed: Full change

Elapsed time: 9 h

Aircraft / Engine: B777‑200 / GE90‑85B

Task completed: Engine removal

Elapsed time: 2 h 50 min

Aircraft / Engine: B747‑400 / RB211

Task completed: Full change

Elapsed time: 4 h 05 min

Aircraft / Engine: A319 / CFM56

Task completed: Full change

Elapsed time: 1 h 55 min

Business impact

By combining validated time savings, reduced manpower requirements and universal fleet compatibility, COBRA delivers measurable return on investment through lower maintenance cost, higher fleet utilisation and accelerated aircraft dispatch. HYDRO continues to refine the platform through data‑driven updates and targeted customer support, reinforcing COBRA’s position as the industry benchmark for ground‑based engine‑change technology.

Up to 70 %; for example, a Trent 1000 change fell from 28 h to 9 h.

COBRA is cleared for both narrow‑ and wide‑body airframes and validated by Airbus & Boeing; adapter kits cover common engine stands, dollies and cradles. Our dedicated Engineering Team will validate compatability based on your specific operational requirments.

Only one operator is needed— the touch‑screen panel automates pillar synchronisation and preload management.

Automatic Pre‑load Maintaining (APM), Lowering Safety Function (LSF), overload protection, emergency lowering and CE/UL certification keep loads within AMM limits throughout the procedure.

The system is in service with over 115 units worldwide, supporting airlines, MROs and OEMs across six continents.