When aircraft reliability and operational efficiency are non-negotiable, RH Aero Systems delivers industry-leading precision tooling—OEM-approved and engineered for the world’s most demanding airframe and engine maintenance environments.

Our legacy spans over 100 years of combined expertise, integrating Rhinestahl’s and HYDRO’s engineering excellence to support every major commercial and military program globally.

Comprehensive, compliant, and built to the exacting standards of Airbus, Boeing, GE Aerospace, CFM International, Pratt & Whitney and Rolls‑Royce.

RH Aero is the exclusive tooling partner for all major OEMs—including Airbus, Boeing, GE Aviation, CFM International, Pratt & Whitney and Rolls‑Royce—ensuring each tool carries authentic OEM data, certifications, and performance guarantees.

- Unrivaled Quality

-

OEM-approved tools built per original equipment specifications.

- Operational Efficiency

-

Streamlined designs reduce maintenance turnaround times.

- Global Compliance

-

ISO 9001 certified manufacturing and quality processes.

- Lifecycle Support

-

Expert guidance from selection to refurbishment - With integration services available

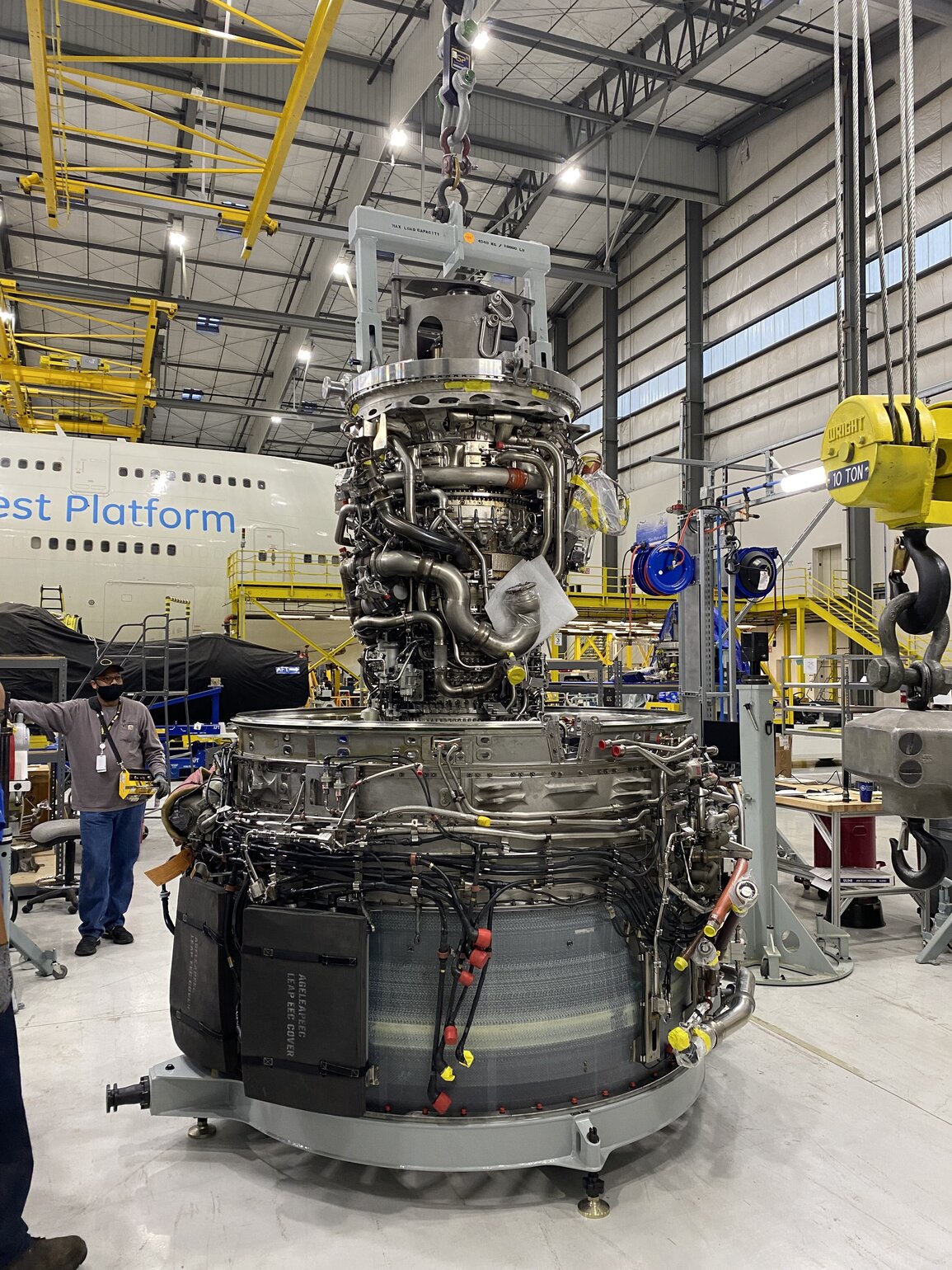

Engine Tooling – 96% fleet coverage

OEM-Approved Solutions:

We provide the industry’s most comprehensive selection of engine tooling, covering 96% of all in-service commercial and regional engines—including CFM, GE, Pratt & Whitney, and Rolls-Royce.

Cutting-Edge Innovation:

From digital-enabled inspection tools like the FutureDriveNG+ to advanced handling and split engine stands, our equipment enables faster, safer, and more precise maintenance—on-wing and in-shop.

Lifecycle Support:

Full spectrum of support: tool design, manufacturing, calibration, recertification, repair, and fleet-wide inventory management.

Readiness, Anywhere:

Rapid access to tooling and technical support through 26 OEM-certified service centers—strategically located for maximum proximity to major operators and MROs.

Why RH Aero Systems?

26 service centers, 100.000+ installed tools, supporting customers in over 120 countries - From concept to deployment, through repair, calibration, and retirement—RH Aero ensures every tool is mission-ready.

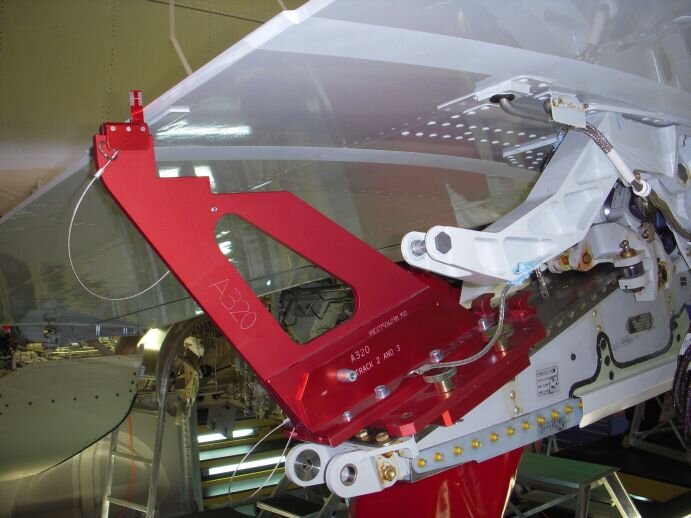

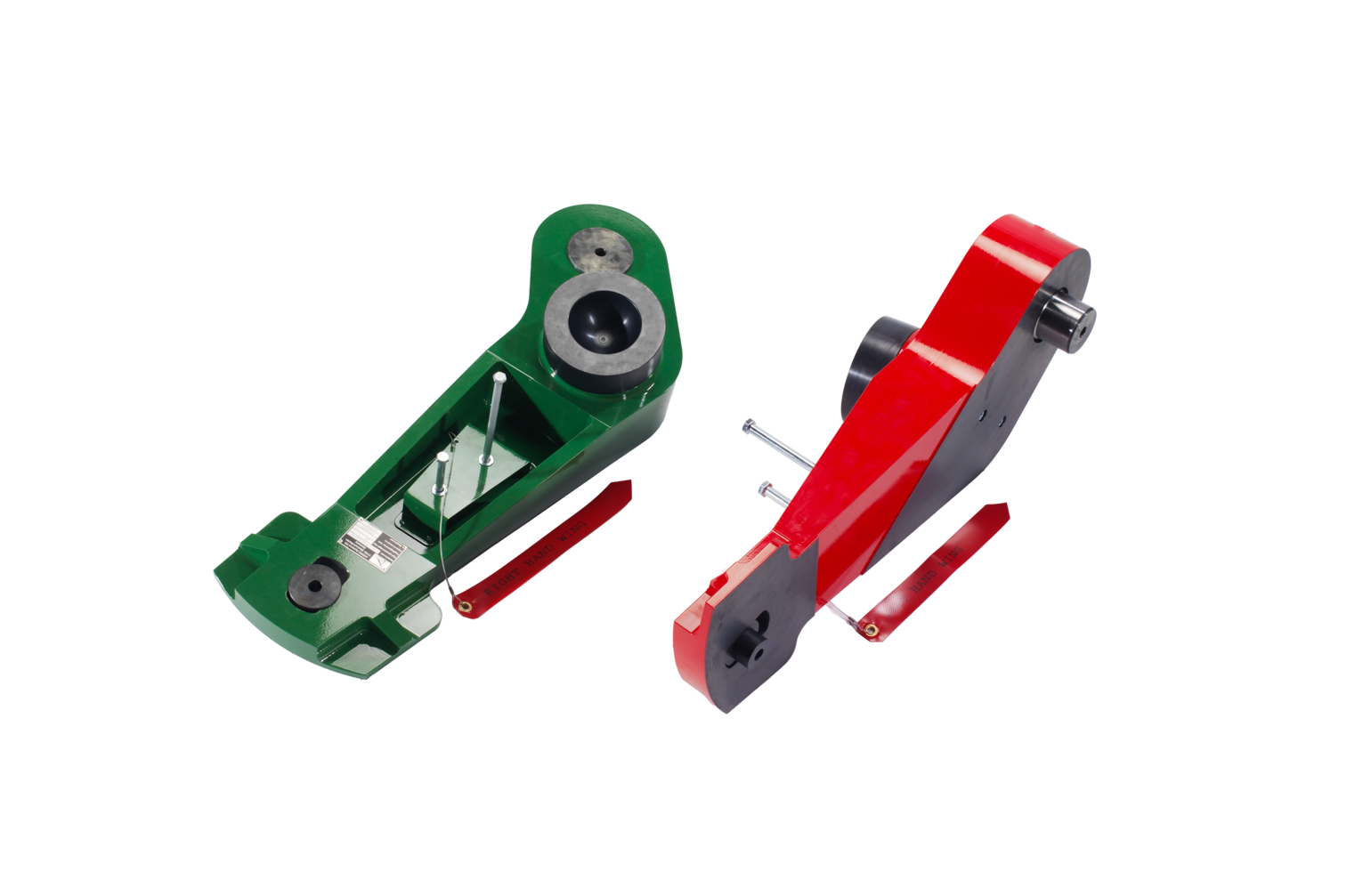

25,000+ Airframe Tooling

Comprehensive Airframe Coverage:

From hydraulic systems, landing gear, and flight control surfaces to airframe structure tools, we support every phase of aircraft maintenance and assembly.

Bespoke Engineering:

In-house engineering capabilities allow us to design, certify, and deliver tailored tooling for both new programs and legacy fleets.

CE & OEM Compliance:

All solutions meet the latest CE, ISO, and OEM certification requirements—ensuring safety, reliability, and global regulatory alignment.

RH Aero Systems’ OEM-approved tools cover virtually all major commercial, regional, and military aircraft and engine platforms. Our portfolio includes tooling solutions for CFM, GE Aerospace, Pratt & Whitney, Rolls-Royce, Honeywell, and IAE engine programs, as well as Airbus, Boeing, Embraer, Sukhoi, and other leading airframe manufacturers. With over 96% global fleet coverage, our tools are designed to support both current and legacy models, ensuring seamless integration into any MRO or operator environment.

All RH Aero Systems tools supplied as OEM-approved carry specific licensing, certification, and documentation that confirms their approval status. Each tool is marked with a unique identification number and is traceable to the corresponding OEM’s approval list or service bulletin. Customers can request certificates of conformity, OEM license letters, or approval documentation directly from RH Aero or by referencing the official OEM tooling catalogs in which our tools are listed.

Our tools are manufactured and certified in accordance with all applicable international and OEM-specific standards. This includes:

- OEM Licensing & Certification (GE, CFM, Pratt & Whitney, Rolls-Royce, Airbus, Boeing, etc.)

- CE Marking and compliance with European safety directives

- ISO 9001 and ISO 3834-2 quality management

- Regulatory and safety standards as required by EASA, FAA, and global aviation authorities

- Each tool is subjected to rigorous quality control and documentation processes to ensure safety, durability, and global regulatory compliance.

Tooling Integration Services by RH Aero Systems provide comprehensive support for implementing, managing, and optimizing tooling fleets within your maintenance operation. This includes:

- Initial tooling needs analysis and gap assessment

- Customization and adaptation of tooling kits for specific platforms or shop layouts

- On-site installation, setup, and commissioning

- Training for technical staff

- Digital inventory management and tracking

- Ongoing calibration, maintenance, and certification services

Our goal is to ensure seamless tooling readiness, maximum efficiency, and full regulatory compliance throughout your operation’s lifecycle.